Unveiling the Secrets: Where Do the Profits and Costs of Drip Molding Primarily Lie?

2026,01,20

Unveiling the Secrets: Where Do the Profits and Costs of Drip Molding Primarily Lie?

Industries Involved: Garment accessories, soft PVC drip molding, soft PVC double-sided zippers, single-sided zippers, shoe embellishments, shoe uppers, shoe soles, shoe trims, luggage pull tabs, single-sided pull tabs, double-sided pull tabs, motorcycle stickers, glove embossing.

For manufacturers of soft PVC drip molding labels, the business is primarily processing-based, without retail sales. Orders come from garment factories, shoe factories, gift trading companies, and cross-border e-commerce businesses. Customers provide samples or design drawings for production. Production costs are high, and manufacturers rely on large orders to maintain meager profits. Drip molding production costs mainly involve three aspects:

1. Labor

2. Materials

3. Molds

Labor: Recruiting and managing labor is difficult. The drip molding industry is very labor-intensive, and labor costs are high with high employee turnover. Labor costs constitute the largest portion of expenses.

Materials: All export products require high-quality materials, resulting in high costs.

Molds: Mold costs are very high. Each sample requires the development of new molds. Every large production run requires the carving of new molds, unless the customer repeatedly places orders, which can save some mold costs, provided there is a large inventory of molds. Therefore, mold costs are also very high.

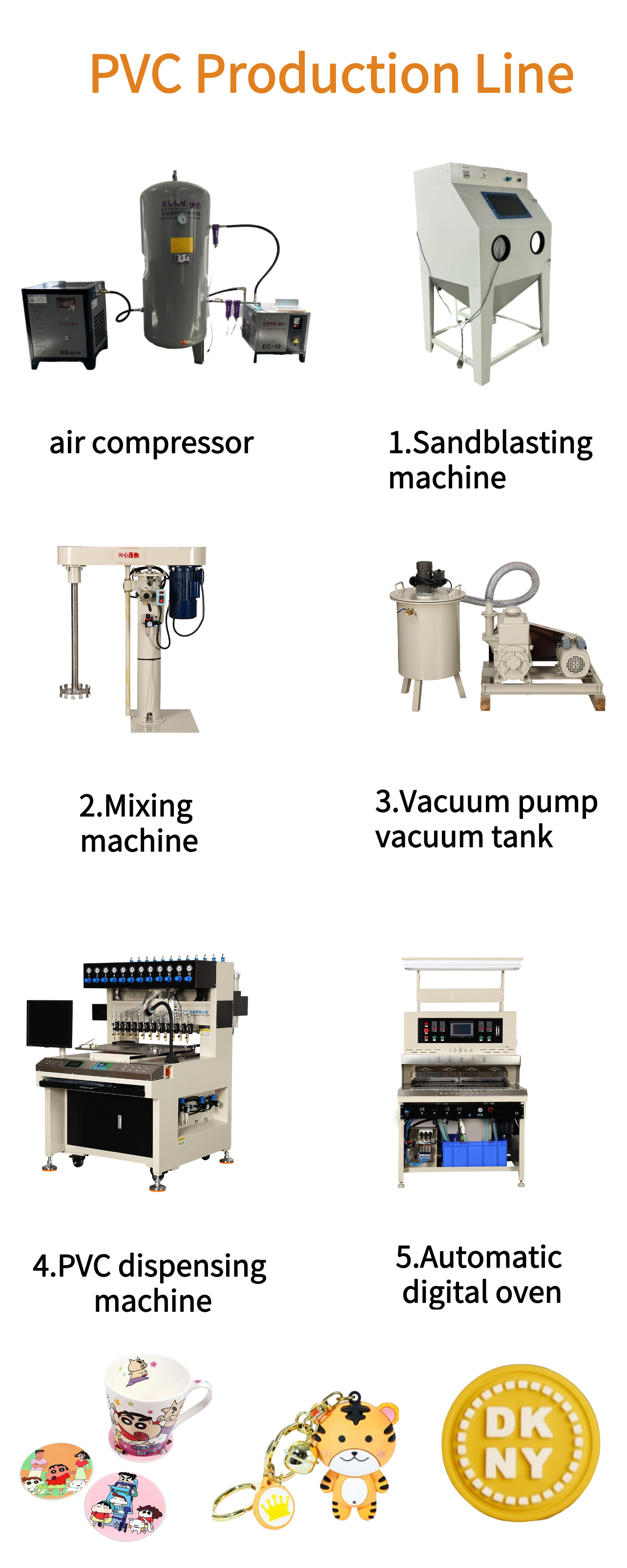

Basic PVC patch production Line:

* dust fliter sand blast machine——it is to treat mold before inject PVC

*mixing machine——it is to mix pvc raw material

*vaccum pump + vacuum mixing barrel——this machine is to take air out from pvc raw material (Ensure the products no bubble)

* PVC patch dispensing machine with UV light——high efficiency and high quality to produce PVC patch

*oven——this is to heat and cool mold