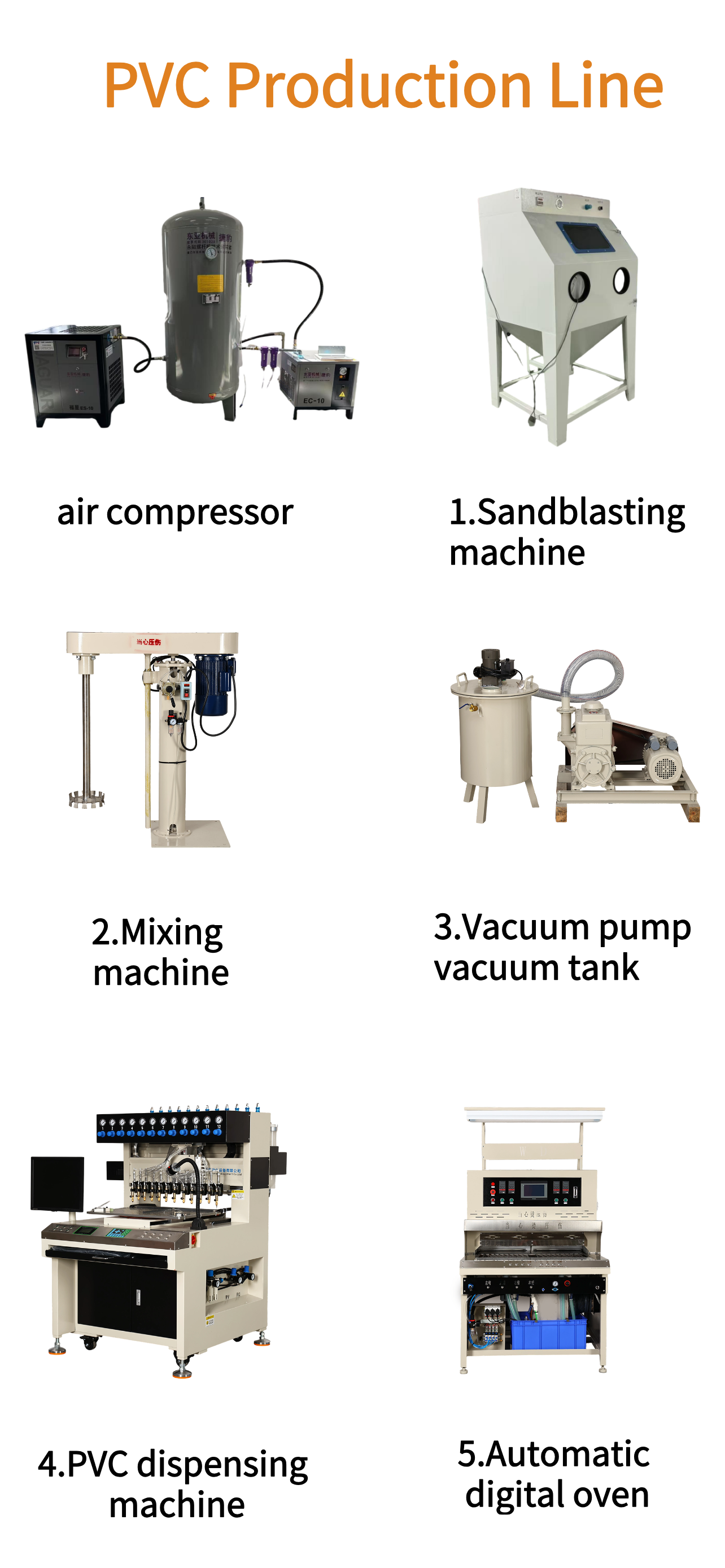

This equipment is used to treat the surface of product molds.

It removes dust, oil, and impurities from the mold, improving the adhesion between the PVC material and the mold.

Additionally, when using needle dispensing, sometimes the mold surface can be scratched, resulting in defective PVC label products.

Our sandblasting machine can be used to treat the mold in such cases.

A clean mold surface ensures clear details, better color representation, and higher product quality.

The

paste mixing machine is used to uniformly mix PVC powder and PVC oil, and to thoroughly mix the resulting PVC paste with pigments and additives.

The uniform mixing ensures stable product color, consistent viscosity, and smooth material flow, which is crucial for the quality of PVC labels.

The Vacuum Pumps and Vacuum Mixing Barrel need to be used together. After the PVC raw materials are thoroughly mixed, they are transferred to the vacuum tank.

The vacuum pump extracts air from the PVC raw materials, preventing bubbles from appearing in the PVC labels.

Vacuum pumps are usually available in 15L, 30L, and 70L specifications, which can be selected according to your order volume.

4.PVC Dispensing Machine with UV lamp

This is the core equipment of the PVC patch production line.

The dispensing machine accurately fills the prepared PVC material into the mold according to the product design.

UV light irradiation allows for simple surface curing of small areas of color, eliminating the need for the fabric part to be baked in an oven, greatly increasing the production speed of PVC patches.

After the PVC raw materials are dispensed, the molds are sent into an electric oven for heating and curing.

The oven has two independent enclosed spaces, allowing for different heating times and temperatures to be set. Once the set time is reached, the molds are automatically ejected from the oven, and cold water is injected onto the cooling table to cool the molds.

After the molds cool, workers can remove the PVC patches from the molds using a picking tool.

The above is a complete set of equipment for a complete PVC patch production line.

This production line is widely used for making PVC logos, PVC brand patches, PVC military patches, PVC cartoon patches, PVC shoe labels, and various PVC promotional products.