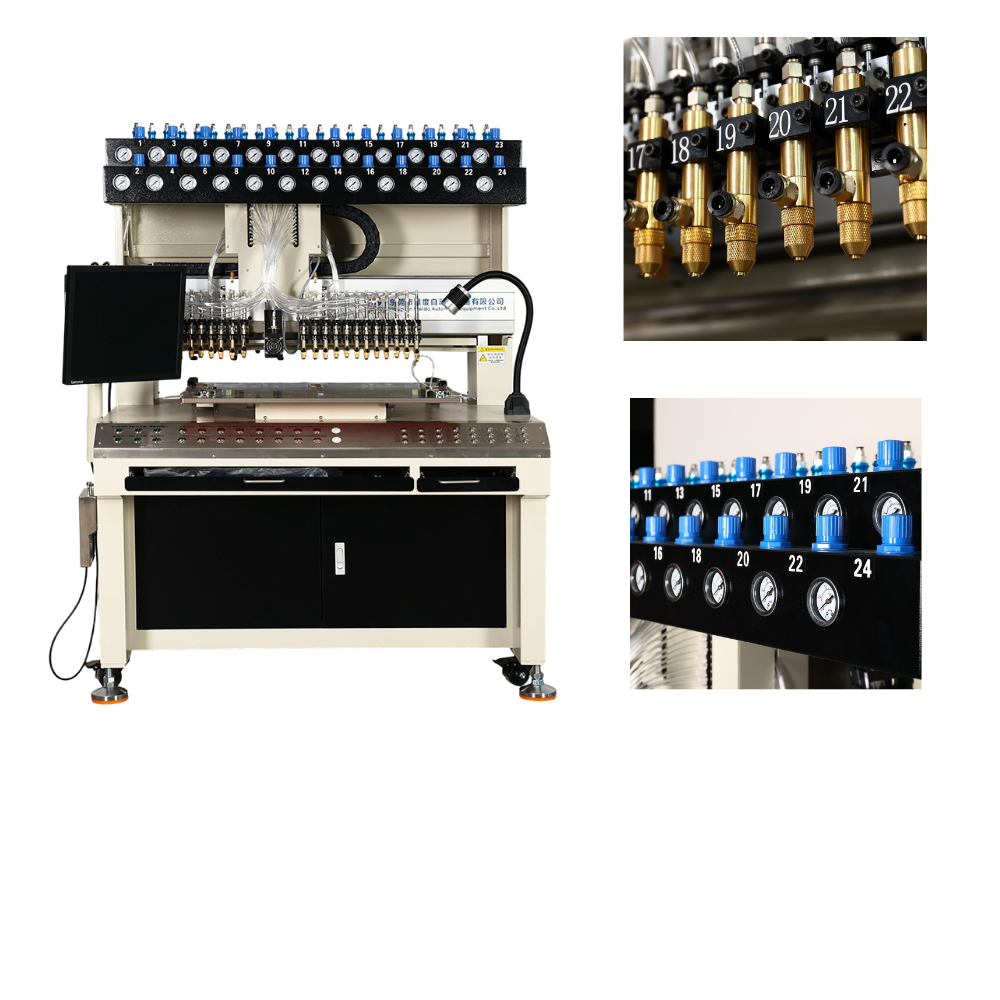

Advantages and Parameters of Weldo Computer Controlled Dispensing Machine:

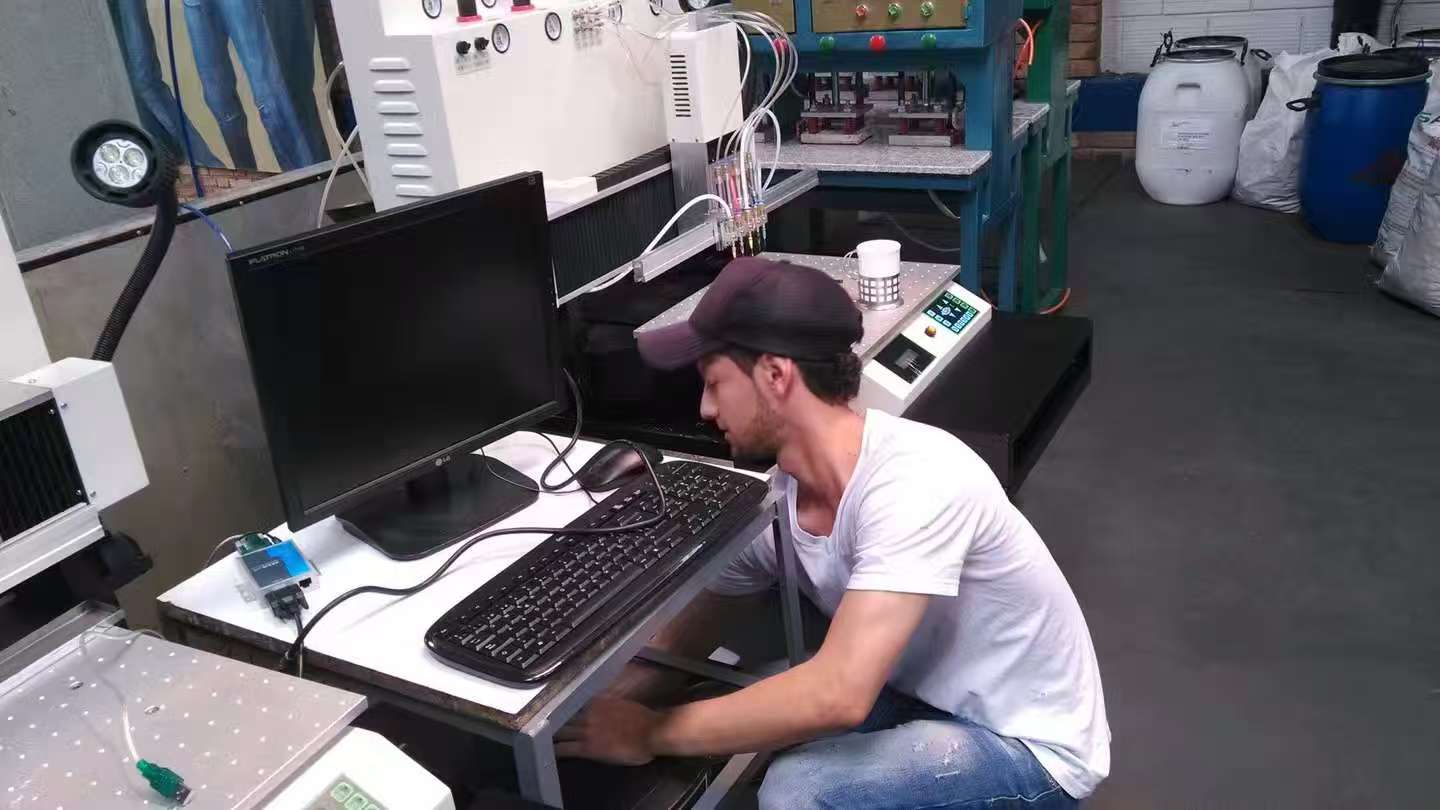

1.High Dispensing Accuracy: Coordinates (X/Y/Z axis precise positioning), glue volume, and dispensing speed can be set via computer programming.

2.Dispensing Parameters Can Be Saved: Dispensing parameters (path, pressure, glue volume, speed) for each product can be stored as a program, which can be directly recalled for subsequent mass production.

3High-Speed Continuous Operation: Computer programming supports multi-path optimization (automatically plans the shortest dispensing route).

4.Reduced Labor Requirements: After setting the program, the equipment can automatically complete dispensing, allowing one person to operate multiple machines simultaneously, significantly reducing labor costs, especially suitable for mass production needs of small and medium-sized factories.

5.Reduced Changeover Time: Dispensing programs for different products can be stored in the computer. When changing orders, the corresponding program can be directly recalled (e.g., switching from keychains to bar mats), eliminating the need for re-debugging, reducing changeover time from 30 minutes to within 5 minutes.

6.Supports Complex Patterns and Processes: Computer programming can achieve dispensing of any 2D pattern.

7.Compatible with Multiple File Formats: Supports importing mainstream design files such as AI, CDR, and DXF. Customer-provided design drawings can be directly converted into dispensing programs without manual drawing or secondary modification, reducing communication costs and error rates.

8.Easy for Beginners: Visual operation interface, simple program editing (drag-and-drop path planning, digital parameter input), beginners can operate independently after 2-3 days of training, no professional programming knowledge required, lowering the employment threshold.

9.Adaptable to Multiple Product Production: The same equipment can produce various products such as PVC keychains, bar mats, shoe uppers, trademarks, and jewelry by switching programs through programming.

10.Avoids Waste and Overflow: Programmed control of dispensing timing and volume precisely matches mold requirements, reducing PVC glue waste.

Your team is professional, patient, and highly experienced in the PVC industry.

These machines are well-designed, easy to operate, and suitable for continuous production.

Even after shipment, you continue to provide detailed guidance and follow-up services.

We would not hesitate to recommend your company to other companies looking for reliable PVC production equipment.