Visual Dispensing Machine

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand. we’ve got preferential price and best-quality products for you.

DONG GUAN WELDO AUTOMATIC EQUIPMENTTECHNOLOGY CO.,LTD

Visual Dispensing Machine

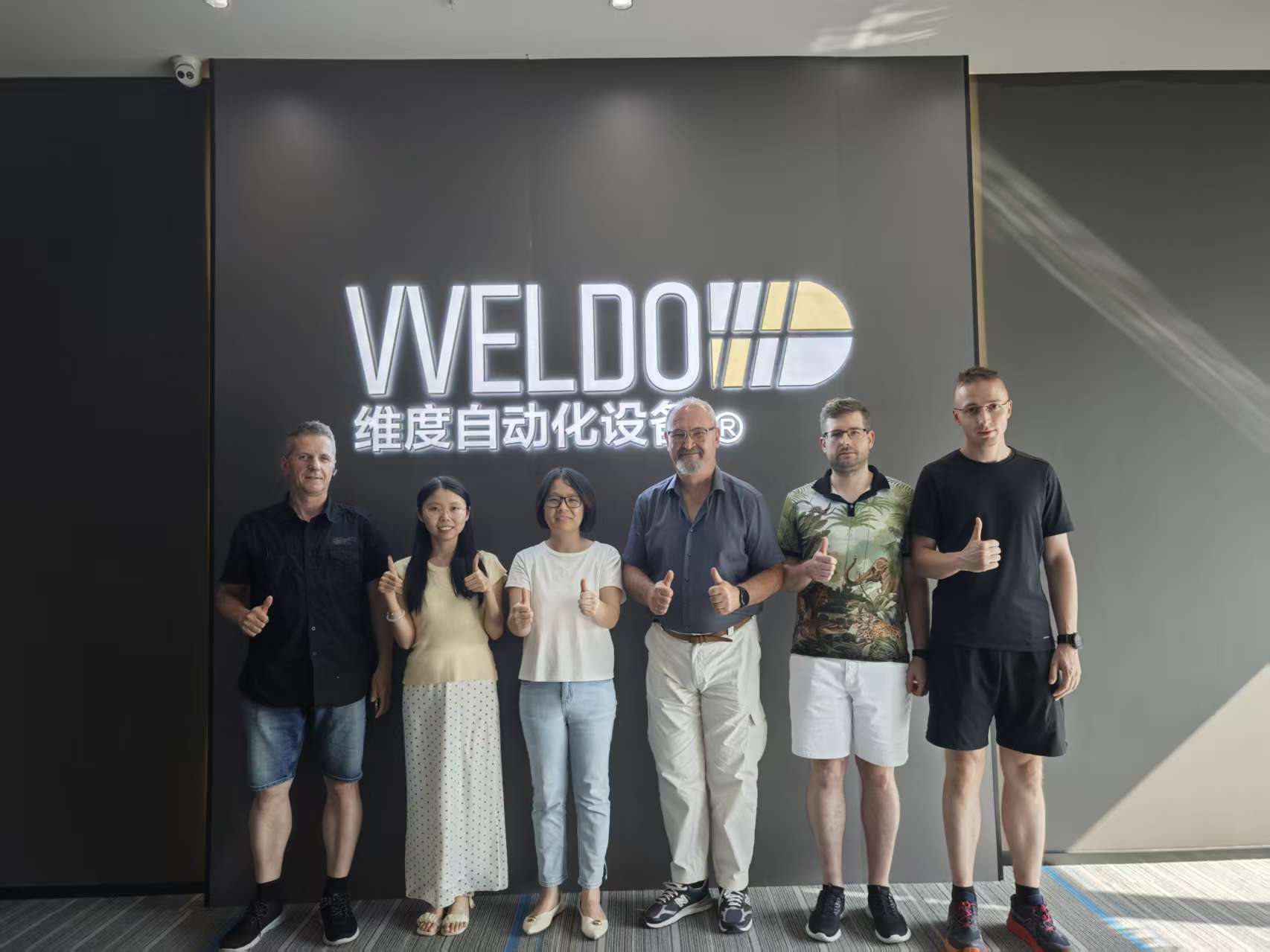

COMPANY SHOW

WELDO

WELDO closely collaborates with leading companies in various industries such as badge manufacturing, footwear materials, nail art, home appliances, and jewelry & silverware, to jointly develop customized visual dispensing and automated assembly equipment.

WELDO’s products are exported to more than 30 countries and regions worldwide, including Germany, the United States, Italy, India, Indonesia, and Brazil. Its core product range covers panoramic vision dispensing machines, badge coloring machines, automatic PVC dispensing machines, fully automatic PVC production lines, intelligent eyelash dispensing machines, visual dispensing and rhinestone machines, and 3D scanning wax setting machines.

In dispensing technology, WELDO applies various advanced valves — including piezoelectric jet valves, pneumatic jetting valves, precision dispensing valves, spray valves, and screw valves — providing professional dispensing solutions for a wide range of fluid materials such as paints, inks, AB glue, UV glue, and hot melt adhesives.

WELDO

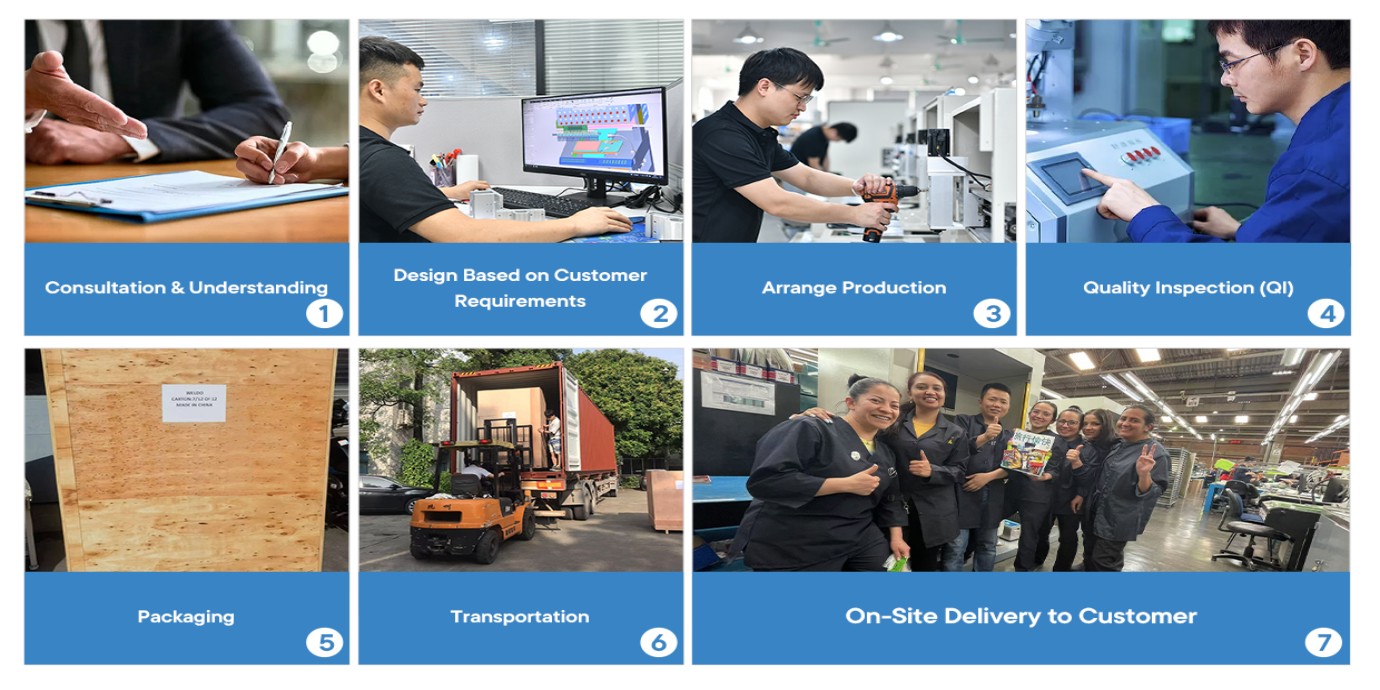

Comprehensive Service Support

1. Requirements Communication

2. Solution Customization

3. Production Testing

4. Training and Delivery

5. After-sales Support

We provide:

1. Detailed installation instructions and operation training videos.

2. Professional online technical support and troubleshooting.

3. Clear machine warranty policy and timely maintenance services.

- 01Intelligent Vision Recognition SystemThe system is equipped with a high-performance industrial vision camera that automatically identifies product position, shape contours, and dispensing paths.

- 02High-Precision Non-Contact Jet Dispensing ValveAdvanced jet dispensing technology enables true non-contact dispensing, allowing adhesive to be accurately deposited without touching the product surface.

- 03High-Speed and Stable Dispensing PerformanceWith high-speed jetting capability, the system greatly reduces cycle time while maintaining excellent repeatability and stability during continuous operation.

- 04Clean, Precise, and Consistent Dispensing ResultsNon-contact dispensing prevents surface damage and contamination, delivering clean and aesthetically pleasing dispensing results. Precise control of dispense volume and jet frequency ensures consistent quality across all products.

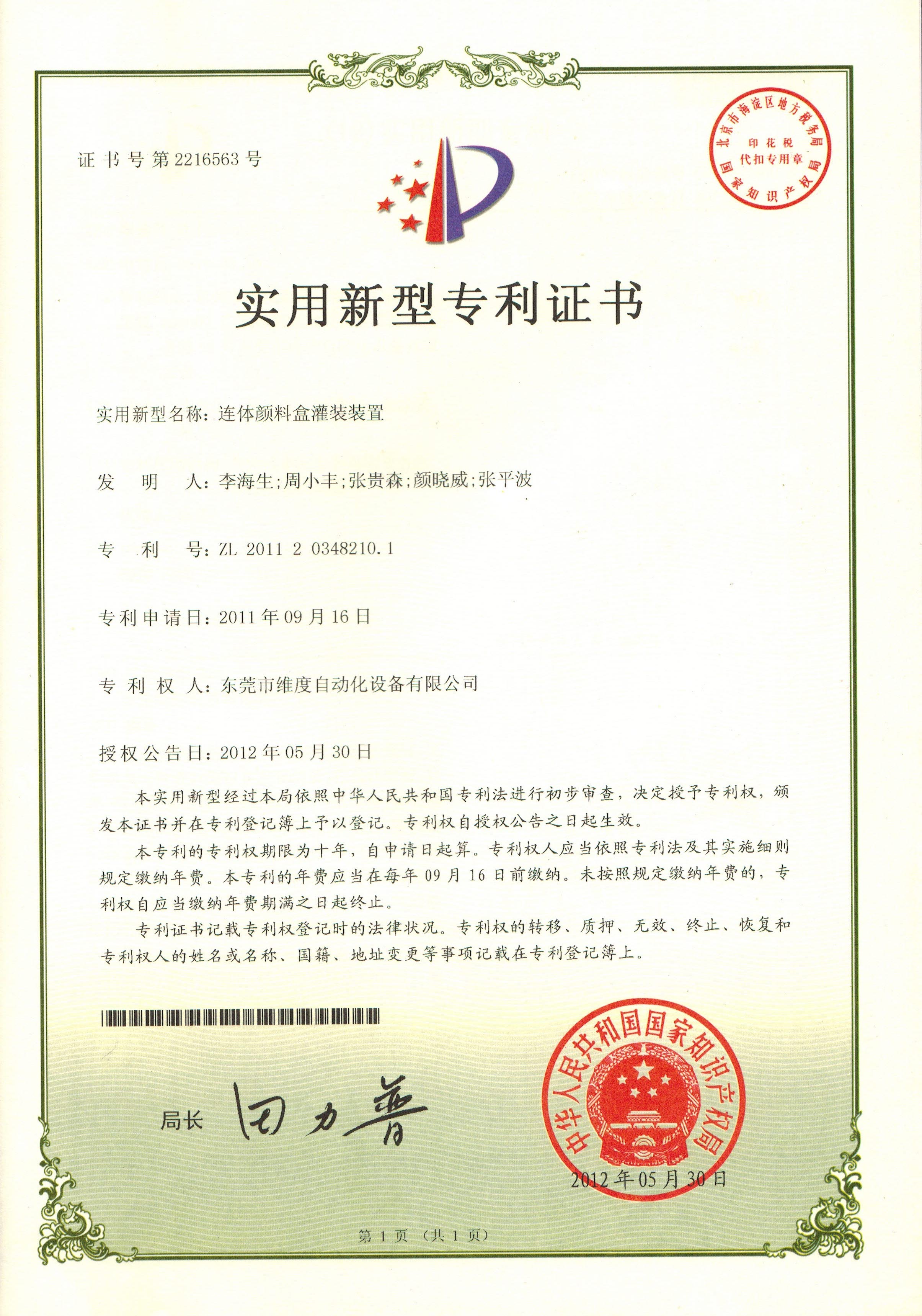

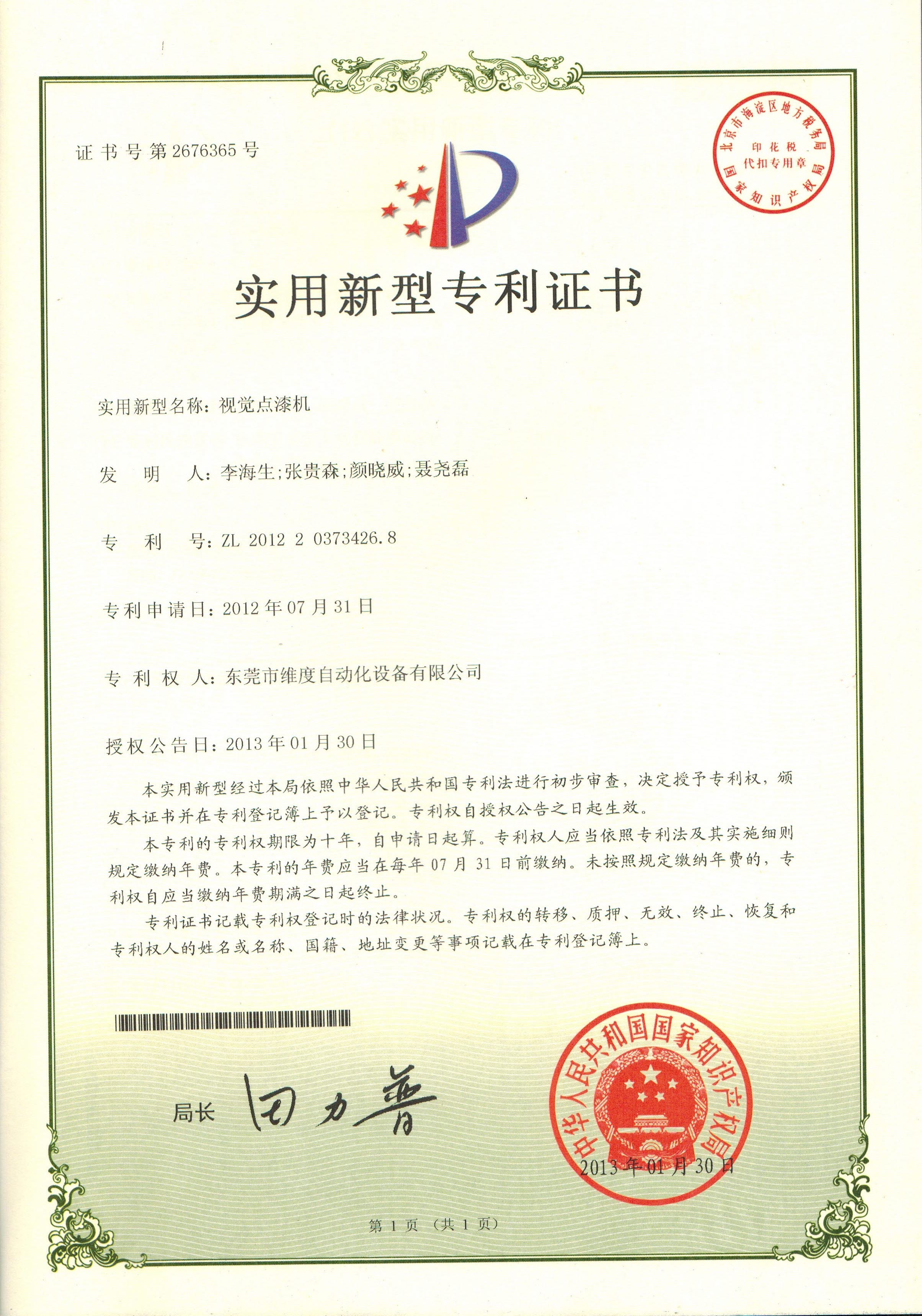

Certificate

We appreciate the ongoing updates and troubleshooting assistance, which ensure our processes run smoothly.